|

This MURI project is focused on a revolutionary new paradigm for fabricating micro/nanodevices: the synergistic use of genetic engineering, biological replication, and shape-preserving chemical conversion to generate enormous numbers of identical Genetically-Engineered Micro/nanodevices (GEMs) with tailored 3-D shapes, fine (meso-to-nanoscale) features, and chemistries.

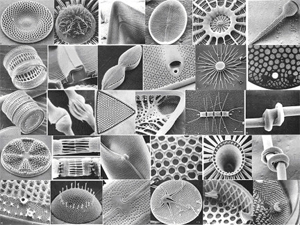

Although appreciable global effort is underway to develop advanced micro/nano-devices for aircraft, biomedical, telecommunications, automotive, and other applications, commercial microfabrication has been largely focused on layer-by-layer (2-D) techniques developed for silicon-based microelectronics. New 3-D methods are needed to enable the low-cost mass production of micro/nanodevices with complex (non-planar) shapes. Nature has developed elegant biological approaches for replicating large numbers of 3-D mineralized (bioclastic) micro/nanostructures. Among the most striking bioclastic structures are the microshells generated by aquatic organisms known as diatoms (Bacillariophyceae). Diatoms are single-celled algae that form microshells comprised of silica nanoparticles that are self-assembled into a dazzling variety of species-specific 3-D shapes (Figure 1). Each of the 100,000 extant diatom species forms a microshell with a unique shape and with distinct patterns of fine features (e.g., regularly-spaced pores, channels, ridges, protuberances) with characteristic dimensions of 102-103 nm. Sustained reproduction (repeated doubling) of a particular diatom species can yield enormous numbers of microshells with identical shapes. For example, 80 sequential reproduction cycles would yield 280 or ~1.2 trillion trillion (more than Avogadro’s number!) microshells with similar shapes and meso/nanoscale features. Such massively parallel and genetically precise self-assembly of 3-D micro/nanostructures under environmentally benign conditions is highly attractive for micro/nanodevice manufacturing. However, such natural bioclastic structures possess a very limited range of compositions (usually SiO2 or CaCO3). The shapes and fine features of such structures are also not tailored for specific microdevice applications

Figure 1. Secondary electron images of the silica-based microshells of various diatom species (from F.E. Round, R.M. Crawford, D.G. Mann, The Diatoms: Biology and Morphology of the Genera, Cambridge University Press, 1990).

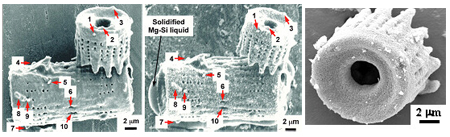

The GEMs paradigm of this MURI project is now feasible owing to recent breakthroughs in: i) the genetics, molecular biology, and biochemistry of diatoms, ii) in vivo and in vitro biosilicification, and iii) near net-shape conversion of biogenic silica. In the latter case, a novel patented process called BaSIC (Bioclastic and Shape-preserving Inorganic Conversion; U.S. Patent No. 7,067,104) has been used to convert biosilica micropreforms into new ceramic compositions with a retention of micropreform shapes and fine features (Figure 2).

Figure 2. Scanning electron microscope images of: a) silica-based diatom microshells and b) the same microshells after conversion into nanocrystalline magnesium oxide via the BaSIC process. 10 specific features retained upon conversion are indicated with red arrows. A higher magnification image of a nanocrystalline magnesium oxide microshell is shown in c) (from Sandhage, et al., Adv. Mater., 14 [6] 429-433 (2002)).

A multidisciplinary team of researchers from academia and the Air Force Research Laboratory has been formed to explore and develop the revolutionary GEMs micro/nanoscale fabrication paradigm. This MURI team is ideally suited for such work, owing to their unique blend of expertise in diatom genetics and biology, in vivo diatom biosilicification, patterned in vitro biosilicification (biosculpting), shape-preserving chemical conversion of biosilica, modeling of micro/nanofluidics, and microdevice fabrication and characterization. Although the team members have already made pioneering breakthroughs related to the GEMs paradigm, significant multidisciplinary basic research remains to be conducted to understand:

- how genetic, biochemical, and environmental factors control the shapes and fine features of diatom-derived structures, and how such factors can be manipulated to generate micro/nanostructures with tailored geometries,

- fundamental mechanisms associated with the shape-preserving conversion of biosilica into a variety of other technically-important functional materials, and

- how to use this new paradigm to develop scaleable microfabrication protocols for mass producing microfluidic and optical devices.

This MURI project is expected to lead to new insights into synergistic coupling of genetics, biochemistry, molecular biology, synthetic inorganic chemistry, and modeling for the fabrication of novel micro/nanodevices for a host of DoD and commercial applications.

Return to top

|